Key Facts

That is why our paving jointing mortars

are water permeable and frost resistant.

PHNA and GFTK keyfacts

In Geotechnology, permeability is used to quantify the permeability of ground and rock for liquids or gases ( i.e. groundwater, crude oil, natural gas ).

See page contributes to active environmental protection

Environmentally friendly construction and ecological actions, are part of the central concept in towns and communities to promote an environment conducive to a good quality of life. This includes preserving historic parts of towns and country, creating leisure and recreational areas including the development of effective biotope systems.

The result of increasing surface sealing, is that there is more surface water. In case of heavy rain, there is a risk of high water and the drainage system is overloaded. This results in poorer quality of our rivers and lakes.

Rainwater is a raw material vital to life and should go back into the natural cycle of things, not into drains. An alternative to the usual method of diverting rainwater is to catch it and let it seep - an environmentally friendly, effective and cost effective solution: rainwater is absorbed by paved stone systems and fed directly back to the ground and groundwater.

On your property you will be able to actively contribute to the environment, by having surfaces strengthened that allow seepage and become de-sealed, allowing near to nature rainwater management. This does not mean you will be deprived of functional or creatively attractive surfaces for paths, terraces or driveways.

A calculated value that quantifies the permeability of water through ground or rock, is called the permeability value or hydraulic conductivity value.

Grainsize is the deciding factor!

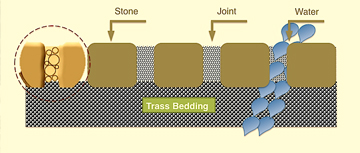

A synthetic resin paving jointing mortar is always made of two components. The first component is binding agent, which is responsible for hardening and stability. The other component is the filler material, which is responsible for water permeability. The filler material component is a washed, firedried silica sand with various grainsizes.

The silica sands have no zero components, unlike cement (cement dust). This means that hollow areas can form, through which water can seep. The size of the hollow areas, which depends on the grainsize, determines the degree of water permeability. Especially during winter, the advantage of large hollow areas is evident. Water, that is still in the joints during ground frost, freezes and is able to expand into the hollow areas. This means cracks and breakage in the joints is avoided

Permeability

Water permeabilty acc. to DIN 18130:

- very highly permeable from 10-2 m/s

- highly permeable 10-2 up to 10-4 m/s

- permeable 10-4 up to 10-6 m/s

- slightly permeable 10-6 up to 10-8 m/s

- very slightly permeable below 10-8 m/s

Earth friendly

Water flows through it:

When precipitation falls onto impermeable surfaces such as standard concrete or asphalt, it cannot drain through the surface and instead must run off toward the lowest point. The associated rain water runoff can negatively impact the environment by decreasing the natural groundwater recharge process, collecting pollutants and washing them into bodies of water thus degrading water quality and contributing to erosion.

GFTK Joint Compound is an exciting new technology that helps prevent these negative effects. When properly installed on a permeable substrate, the water flow rate through GFTK Joint Compound is comparable to that of pervious concrete at 130+ inch/hour.

The installation of pervious concrete is a labor intensive process that requires precise mixing, compacting, working and curing in order to achieve maximum results. Our product is premixed, easy to install, self curing... it's ready when you are.

Greener hardscapes:

Usually we don't think of hardscaping as "eco-friendly" or "green". While the stone paving industry is moving to permeable pavers to help protect our environment, GFTK Joint Compound gives you the opportunity to have permeable and durable joints with any type of stone. But we don't stop there. In addition to exceptional water permeability, our product has additional features that allow you to approach your project with an even lighter impact on the environment:

- All natural and non toxic

- Contains no artificial dyes

- Cleanup does not require any solvents, acids, or other chemicals

- Unused product can be kept for later use

- The finish is durable and long lasting

GFTK Joint Compound, Easy, Safe, and Clean. We've changed the landscape of the stone paving industry.